Additive Manufacturing

Rapid prototyping and production-grade 3D printing using high-performance materials. Perfect for quick product development and testing.

From Digital Design to Physical Part — Layer by Layer

Additive Manufacturing is the process of creating parts by adding material layer by layer, directly from a 3D digital model.Unlike traditional subtractive methods, it enables complex geometries, rapid prototyping, and on- demand production — all with minimal material waste.

At Syntrof Tech, we leverage this process to help customers:

- 1) Accelerate product development with fast, low-cost prototypes

- 2) Reduce tooling costs for short-run or custom production

- 3) Create intricate designs that are impossible with conventional machining

- 4) Experiment, iterate, and launch new ideas faster

Whether you're developing a single prototype or exploring lightweight, complex components for real-world use — Additive Manufacturing opens the door to agility, efficiency, and design freedom.

Solutions

We are providing below solutions in Additive Manufacturing

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results.

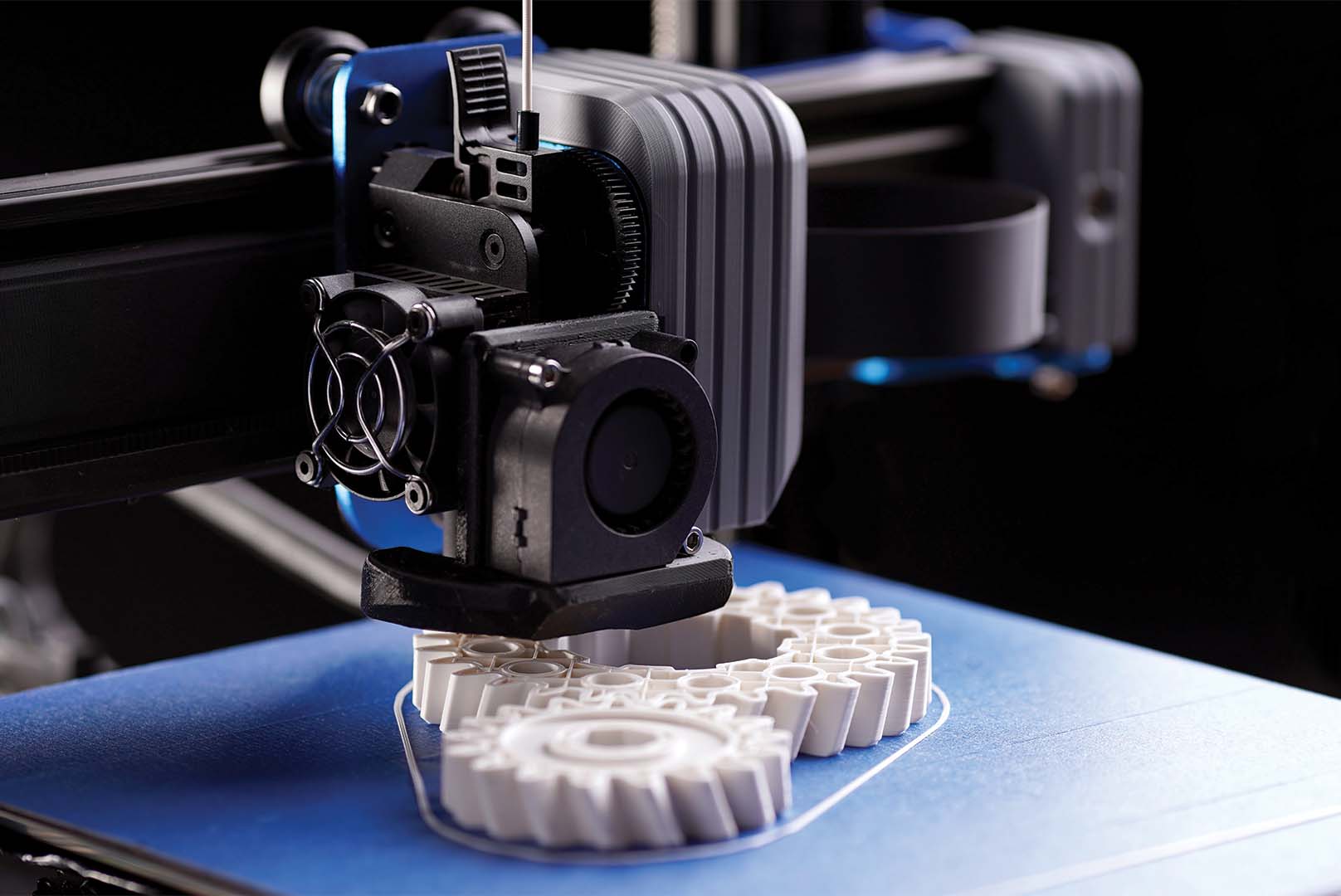

Fused Deposition Modeling (FDM)

Cost-Effective, Rapid, and Reliable Prototyping

FDM is a widely used 3D printing method where thermoplastic filament is heated and extruded layer by layer to build parts directly from a CAD model. It's ideal for quick-turn prototypes, functional testing, and low-cost end-use components.

- 1) PLA, ABS, PETG, Nylon, and engineering-grade filaments

- 2) Rapid prototyping and design iterations

- 3) Functional fixtures, jigs, housings, and mechanical parts

- 4) Large-format prints and low-cost batch production

Note: FDM offers excellent strength-to-cost ratio, material versatility, and quick lead times — making it a go- to choice for product development cycles and iterative design.

Stereolithography (SLA)

High-Precision, Smooth-Surfaced Prototypes

SLA is a resin-based 3D printing process that uses a UV laser to cure liquid photopolymer layer by layer. Known for its exceptional surface finish and fine feature resolution, SLA is ideal for detailed models, visual prototypes, and tight-tolerance components.

- 1) High-detail prototypes, visual models, and design validation

- 2) Complex geometries with intricate surface textures

- 3) Applications in medical, dental, consumer electronics, and wearables

- 4) Functional testing where precision and appearance matter

Note: SLA delivers sharp detail, tight tolerances, and smooth finishes — making it perfect for high-fidelity parts where aesthetics and precision are key.

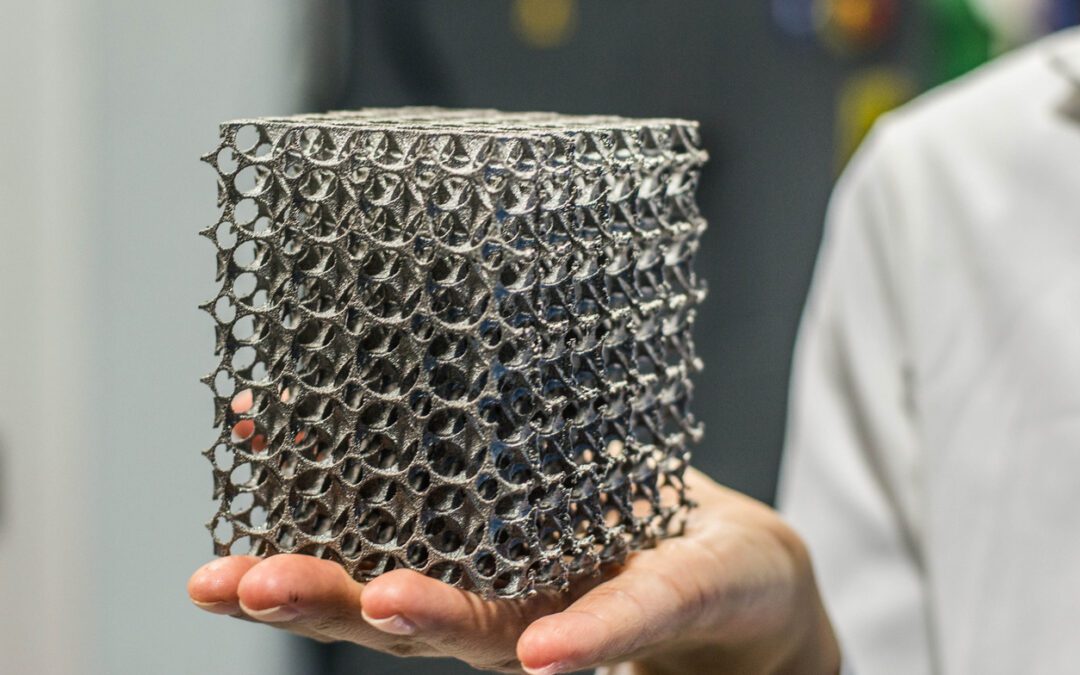

Metal 3D Printing

Complex Metal Parts. Lightweight. High-Strength. No Tooling.

Metal 3D Printing — primarily through Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) — builds fully dense metal parts layer by layer using high-powered lasers. It enables production of geometrically complex, lightweight, and performance-critical components without the need for molds or tooling.

- 1) Aerospace, automotive, medical implants, and tooling inserts

- 2) Lightweight structures with internal channels and lattice geometries

- 3) Functional metal prototypes and end-use parts

- 4) Materials like stainless steel, titanium, Inconel, and aluminum alloys

Note: Metal AM offers unparalleled design freedom, material efficiency, and fast iteration for parts that traditionally require complex machining or casting setups.

Why choose Syntrof Tech

Choosing the Right Manufacturing Partner Matters Here’s Why Syntrof Tech Stands Out Every Time

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof Tech, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results. Whether you're creating prototypes, scaling production, or launching a new product, our team is committed to helping you succeed — every step of the way choose Syntrof tech and experience the difference that quality, experience, and innovation bring to your business.

Highest Quality

100+ Organized Manufacturing Vendors

Cutting-Edge Technology

Transparent Workflow Coordination

Fast Turnaround Time

Cost-Effective Solutions

Our Capabilities

Explore Our Complete Range of Manufacturing and Product Development Capabilities

At Syntrof Tech, we offer a wide range of manufacturing and product development services to meet the growing demands of businesses across the globe. From rapid prototyping to large-scale production, our solutions are designed for speed, precision, and cost-efficiency. Explore our core services below and find the perfect solution for your next project.

Additive Manufacturing

Rapid prototyping and production-grade 3D printing using high-performance materials. Perfect for quick product development and testing.

CNC Machining

High-precision CNC milling, turning, and drilling services for metal and plastic parts with tight tolerances and fast delivery.

Sheet Metal Fabrication

Custom sheet metal components for automotive, construction, and industrial use. High strength, clean finishes, and flexible designs.

Casting & Forging

Precision forging and casting solutions for OEMs and industrial manufacturing applications.

Injection Molding

From prototype molds to full-scale production runs. Efficient molding processes for plastic parts with consistent quality.

New Product Development

Complete design to manufacturing services. Transform your idea into a market-ready product with expert support at every stage.

For all the reasons which brought you here

Let's Connect!

Follow Us on

Stay connected with our Insights, innovations, and updates

frequently asks questions

Real Stories From Satisfied Customers Who Trust Our Manufacturing Expertise in India

At Syntroftech, client satisfaction is not just a goal – it’s our commitment. Here’s what business owners, engineers, and product developers from across India have to say about partnering with us. From startups to large enterprises, their words inspire us to push boundaries every day!

What industries does Syntrof Tech serve?

We serve Automotive, Industrial, Electronics, Construction, Education, Electric Vehicles, Agriculture, Solar, Architecture, and Healthcare sectors across India.

Can you handle bulk manufacturing orders?

Yes, we specialize in both small batch and bulk production with high quality standards.

How fast can you deliver 3D printed prototypes?

Depending on the design complexity, we usually deliver prototypes within 3 to 7 working days.

Which materials are available for CNC machining?

We offer metals like aluminum, steel, copper, and plastics like ABS, POM, and others.

Is product design assistance available?

Yes, our design team can assist you from concept development to prototyping.

Can you create custom sheet metal parts for industrial machinery?

Absolutely! We specialize in custom sheet metal fabrication for various industries.

What is the typical lead time for injection molding projects?

Injection molding projects usually take 2 to 6 weeks depending on tooling and order size.

How do you ensure the quality of manufactured parts?

We follow strict quality control protocols, including material testing and final inspection before dispatch.