Injection Molding

From prototype molds to full-scale production runs. Efficient molding processes for plastic parts with consistent quality.

Scalable. Repeatable. Production-Ready.

Injection Molding is a high-efficiency manufacturing process where molten material — typically plastic — is injected into a mold to form parts with complex shapes and tight tolerances. It’s the industry standard for mass production, offering consistency, speed, and cost efficiency at scale.

At Syntrof Tech, our Injection Molding services enable customers to:

- 1) Produce high volumes of parts with uniform quality and detail

- 2) Use a wide range of engineering-grade plastics and materials

- 3) Create robust components for consumer products, electronics, automotive, and more

- 4) Reduce unit cost through optimized mold design and cycle efficiency

From tooling development to material selection and part validation, we manage the entire process — helping you scale from prototype to production with confidence. When you’re ready to scale, Injection Molding delivers — and we make it seamless.

Solutions

We are providing below solutions in Injection Molding

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results.

High-Density Polyethylene (HDPE) Injection Molding

Tough. Flexible. Chemical-Resistant.

HDPE Injection Molding specializes in creating durable, lightweight, and corrosion-resistant plastic parts using High-Density Polyethylene. HDPE is ideal for industrial, packaging, and consumer products due to its impact strength and low moisture absorption.

- 1) Containers, caps, tanks, automotive parts, piping components

- 2) High chemical resistance and outdoor durability

- 3) Flexible yet tough applications requiring lightweight performance

Note: It’s widely used in sectors like agriculture, automotive, packaging, and utilities due to its recyclability and cost-effectiveness.

Quick Turn Injection Molding

Rapid. Agile. Bridge Between Prototype & Production.

Quick Turn Injection Molding enables accelerated tool development and part production, making it ideal for iterative testing, short runs, or market entry before full-scale tooling.

- 1) MVPs, pre-launch units, pilot builds, and low-volume orders

- 2) Fast lead times — typically within days to weeks

- 3) Thermoplastics including ABS, PC, Nylon, HDPE, and more

Note: This is perfect for startups and R&D teams that need speed, flexibility, and low upfront cost.

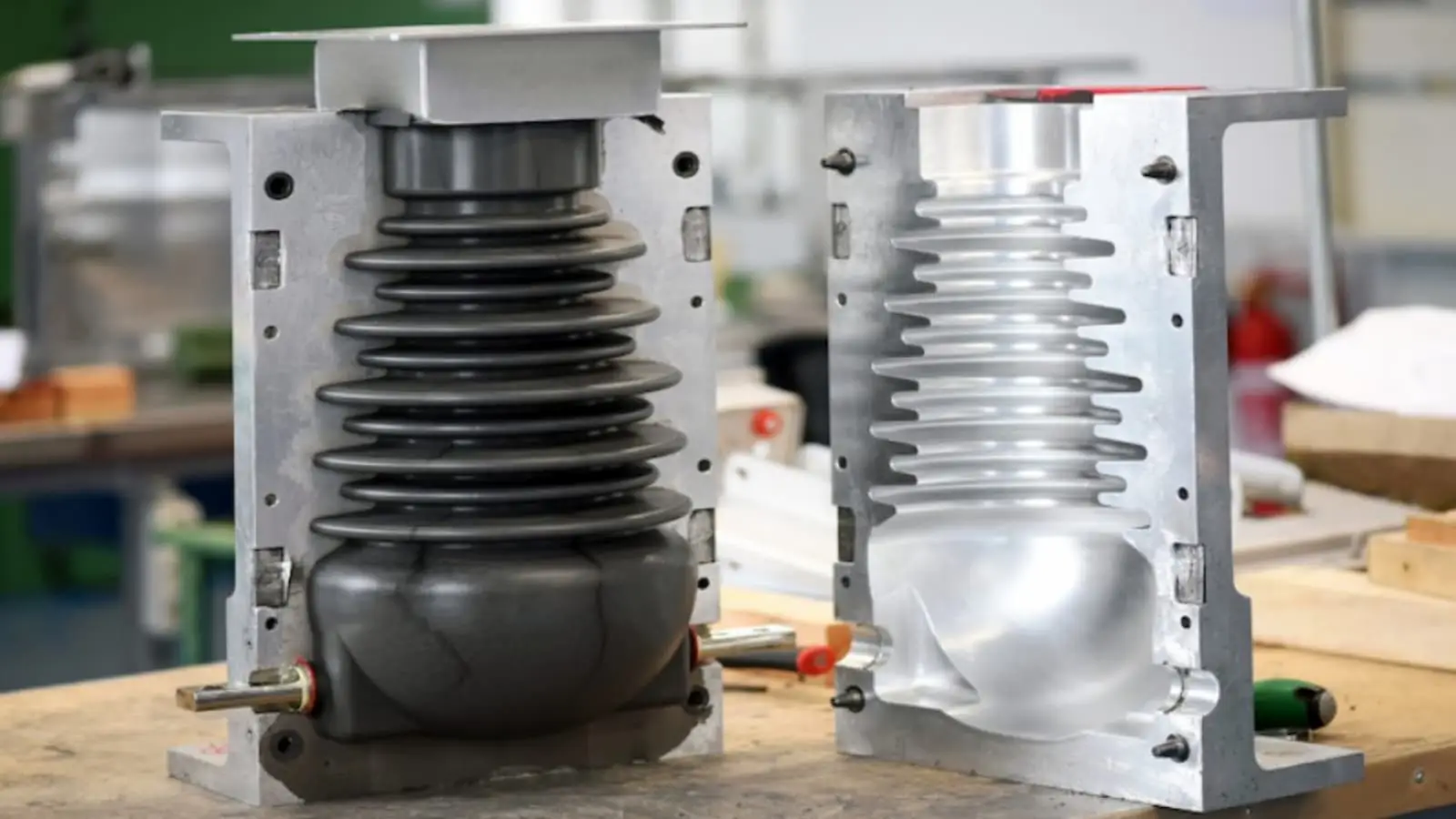

Blow Molding

Hollow Parts. Lightweight. High Volume.

Blow Molding forms hollow plastic parts by inflating a heated plastic tube (parison) inside a mold. It’s the go-to process for high-volume production of uniform, thin-walled containers.

- 1) Bottles, tanks, ducts, containers, automotive reservoirs

- 2) Polyethylene, polypropylene, PET, and other moldable plastics

- 3) High-speed, cost-efficient hollow part manufacturing

Note: Used across packaging, consumer goods, medical, and automotive, blow molding offers low material waste and scalable production.

Compression Molding

High Strength. Fiber-Reinforced. Large Part Friendly.

Compression Molding uses heat and pressure to mold thermoset resins or composites in a closed cavity. It’s great for high-strength, large-sized, and structural components.

- 1) Electrical housings, panels, bumpers, and composite parts

- 2) SMC, BMC, epoxy, phenolic, and reinforced plastics

- 3) Low to medium production volumes requiring performance over precision

Note: It is commonly used in automotive, aerospace, and electrical insulation for its excellent mechanical properties and cost- efficiency.

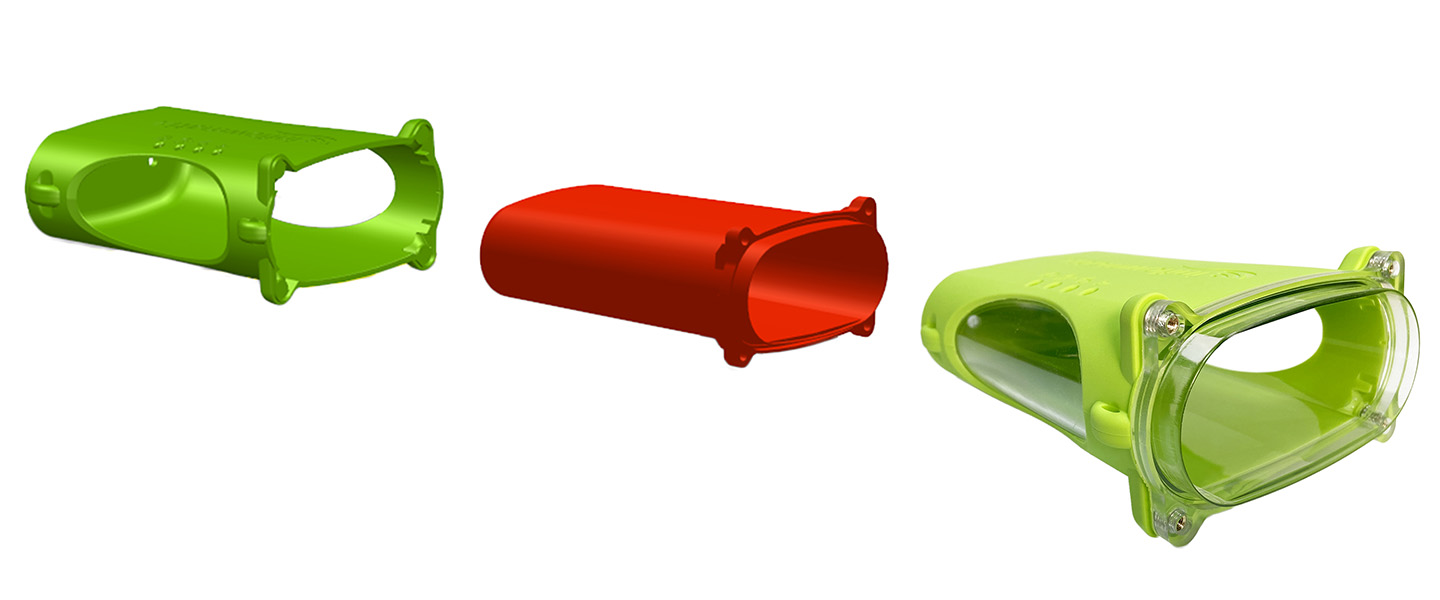

Overmolding

Multi-Material Integration. Enhanced Functionality.

Overmolding involves molding a second material over a pre-molded part — allowing integration of soft-touch surfaces, seals, grips, or multiple functionalities into one component.

- 1) Handles, grips, buttons, seals, enclosures

- 2) Combining rigid (ABS, PC) and soft (TPU, TPE) materials

- 3) Improved ergonomics, aesthetics, and part consolidation

Note: Used in consumer electronics, tools, medical devices, and automotive, overmolding adds value without added complexity.

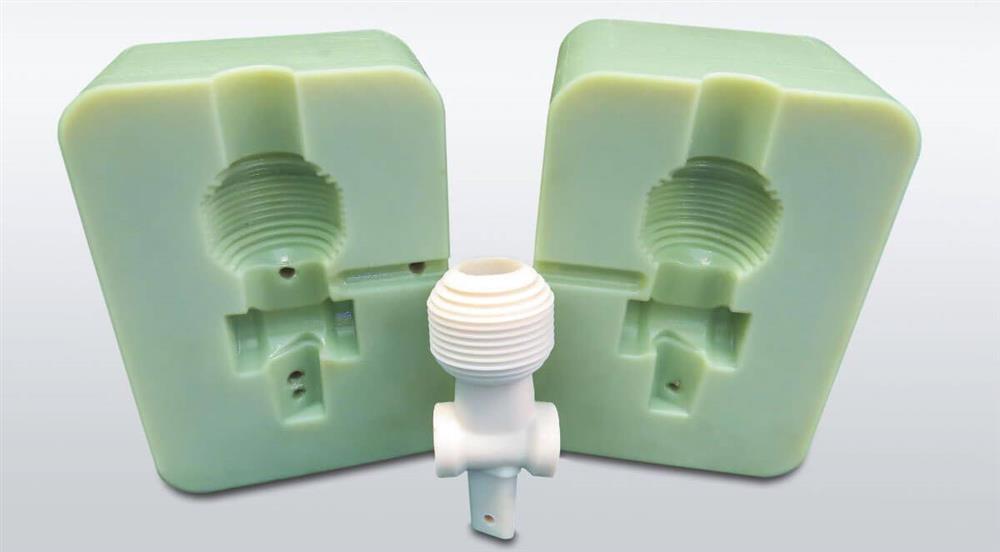

Prototype & Production Molding

From One-Offs to Millions — Seamless Scaling.

This service bridges the full product lifecycle — from functional prototype tooling for design validation to production-grade molds for high-volume manufacturing.

- 1) Early-stage testing and iteration

- 2) Launch-to-scale transitions

- 3) Single cavity prototypes or multi-cavity production tooling

Note: Whether it’s low-volume pilot runs or long-term mass production, we deliver speed, quality, and consistency across every stage.

Why choose Syntrof Tech

Choosing the Right Manufacturing Partner Matters Here’s Why Syntrof Tech Stands Out Every Time

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof Tech, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results. Whether you're creating prototypes, scaling production, or launching a new product, our team is committed to helping you succeed — every step of the way choose Syntrof tech and experience the difference that quality, experience, and innovation bring to your business.

Highest Quality

100+ Organized Manufacturing Vendors

Cutting-Edge Technology

Transparent Workflow Coordination

Fast Turnaround Time

Cost-Effective Solutions

Our Capabilities

Explore Our Complete Range of Manufacturing and Product Development Capabilities

At Syntrof Tech, we offer a wide range of manufacturing and product development services to meet the growing demands of businesses across the globe. From rapid prototyping to large-scale production, our solutions are designed for speed, precision, and cost-efficiency. Explore our core services below and find the perfect solution for your next project.

Additive Manufacturing

Rapid prototyping and production-grade 3D printing using high-performance materials. Perfect for quick product development and testing.

CNC Machining

High-precision CNC milling, turning, and drilling services for metal and plastic parts with tight tolerances and fast delivery.

Sheet Metal Fabrication

Custom sheet metal components for automotive, construction, and industrial use. High strength, clean finishes, and flexible designs.

Casting & Forging

Precision forging and casting solutions for OEMs and industrial manufacturing applications.

Injection Molding

From prototype molds to full-scale production runs. Efficient molding processes for plastic parts with consistent quality.

New Product Development

Complete design to manufacturing services. Transform your idea into a market-ready product with expert support at every stage.

For all the reasons which brought you here

Let's Connect!

Follow Us on

Stay connected with our Insights, innovations, and updates

frequently asks questions

Real Stories From Satisfied Customers Who Trust Our Manufacturing Expertise in India

At Syntroftech, client satisfaction is not just a goal – it’s our commitment. Here’s what business owners, engineers, and product developers from across India have to say about partnering with us. From startups to large enterprises, their words inspire us to push boundaries every day!

What industries does Syntrof Tech serve?

We serve Automotive, Industrial, Electronics, Construction, Education, Electric Vehicles, Agriculture, Solar, Architecture, and Healthcare sectors across India.

Can you handle bulk manufacturing orders?

Yes, we specialize in both small batch and bulk production with high quality standards.

How fast can you deliver 3D printed prototypes?

Depending on the design complexity, we usually deliver prototypes within 3 to 7 working days.

Which materials are available for CNC machining?

We offer metals like aluminum, steel, copper, and plastics like ABS, POM, and others.

Is product design assistance available?

Yes, our design team can assist you from concept development to prototyping.

Can you create custom sheet metal parts for industrial machinery?

Absolutely! We specialize in custom sheet metal fabrication for various industries.

What is the typical lead time for injection molding projects?

Injection molding projects usually take 2 to 6 weeks depending on tooling and order size.

How do you ensure the quality of manufactured parts?

We follow strict quality control protocols, including material testing and final inspection before dispatch.