CNC Machining

High-precision CNC milling, turning, and drilling services for metal and plastic parts with tight tolerances and fast delivery.

Precision Engineering at Its Finest

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process where material is precisely removed from a solid block using automated tools, based on digital designs. Known for its exceptional accuracy, repeatability, and tight tolerances, CNC is ideal for both prototyping and end-use production.

At Syntrof Tech, our CNC capabilities help customers:

- 1) Manufacture parts with high dimensional accuracy and superior surface finish

- 2) Handle a wide range of materials — including metals, plastics, and composites

- 3) Produce anything from single prototypes to high-volume batches

- 4) Meet strict industry standards for automotive, aerospace, medical, and more

Whether you need rapid tooling, complex metal components, or consistent part quality at scale, CNC Machining delivers strength, speed, and scalability.

Solutions

We are providing below solutions in CNC Machining

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results.

Custom CNC Machining

Precision Parts. Tight Tolerances. Scalable Output.

Custom CNC Machining involves subtractive manufacturing using computer-controlled tools to cut, mill, drill, and turn solid materials into exact parts. It’s ideal for producing tight-tolerance, high-strength, and complex geometry components in both metals and plastics.

- 1) Prototypes, one-offs, and low-to-high volume production

- 2) Parts requiring ±0.01 mm tolerances

- 3) Complex 3D surfaces, undercuts, threads, and fine detailing

- 4) Materials like aluminum, steel, brass, copper, POM, PTFE, and more

Note: With multi-axis CNC mills, lathes, and turning centers, we deliver high-quality custom components with consistent accuracy, short lead times, and reliable repeatability — from rapid prototyping to production-ready batches.

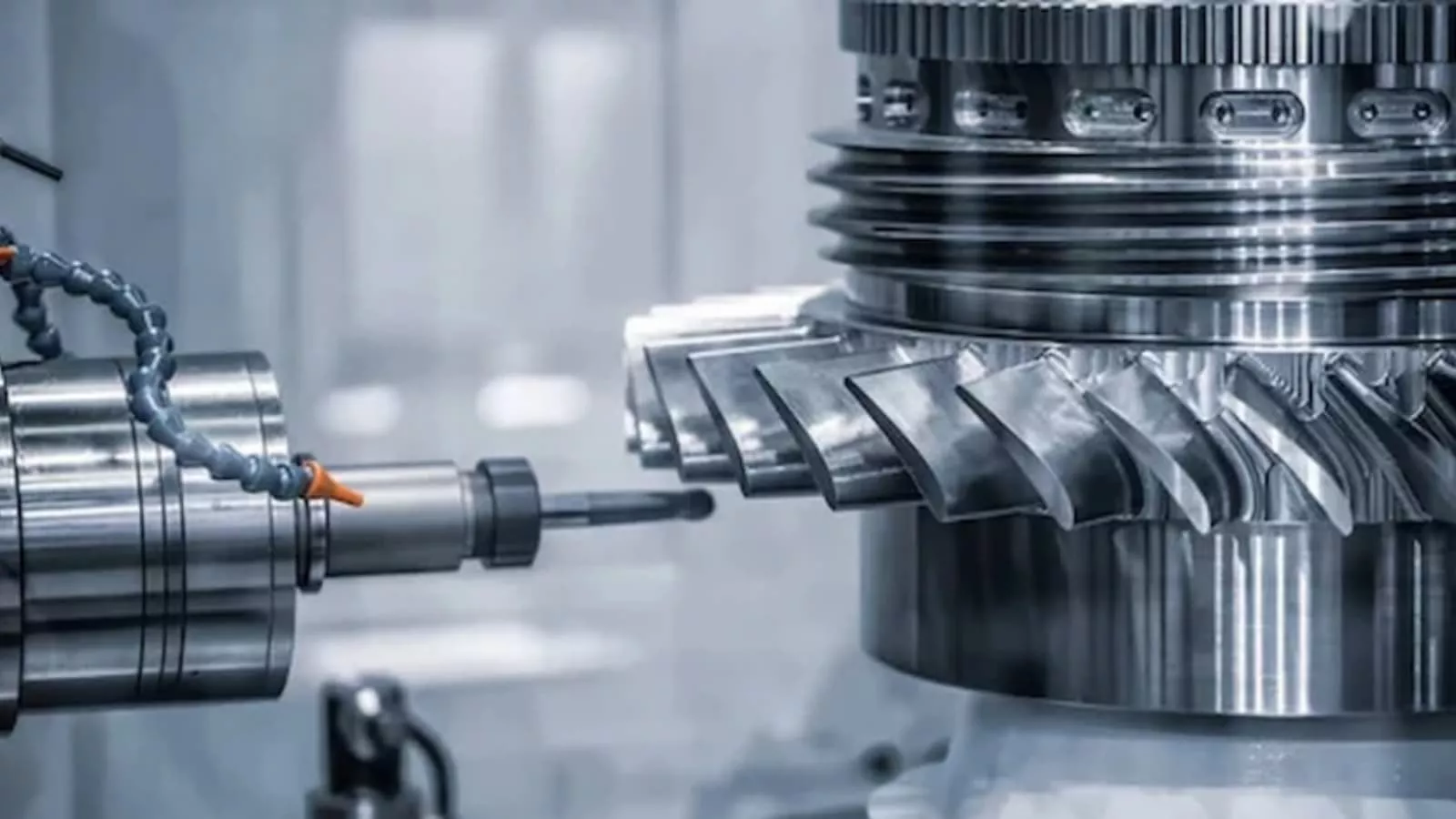

CNC Milling

Complex Geometry. Flat Surfaces. High Precision.

CNC Milling is a subtractive machining process that uses rotating multi-point cutting tools to remove material from a solid block. It’s ideal for producing 2D and 3D geometries, flat faces, pockets, slots, and contoured surfaces with high dimensional accuracy.

- 1) Prismatic parts and complex 3D profiles

- 2) Tooling, enclosures, brackets, housings, and molds

- 3) Tolerance-critical components (up to ±0.01 mm)

- 4) Metals (Aluminum, Steel, Titanium) and plastics (ABS, Nylon, Delrin)

Note: With 3-axis to 5-axis capabilities, our CNC milling services offer tight tolerances, excellent surface finishes, and repeatability — perfect for both prototypes and production runs.

CNC Drilling

Accurate Holes. Fast Cycles. Consistent Depth.

CNC Drilling is a precision process designed to create accurate, repeatable holes in metal or plastic components using rotating drill bits under computer control. It’s essential for parts requiring tapped holes, countersinks, or tight-position tolerances.

- 1) Components with multiple holes, patterns, or deep bores

- 2) Threaded holes, counterbores, and precise alignment features

- 3) High-speed production with minimal manual intervention

- 4) Materials like aluminum, steel, brass, PEEK, and acrylic

Note: Our CNC drilling capabilities ensure tight positioning, controlled depth, and clean finishes — making it ideal for mechanical assemblies, enclosures, brackets, and machined sub-components.

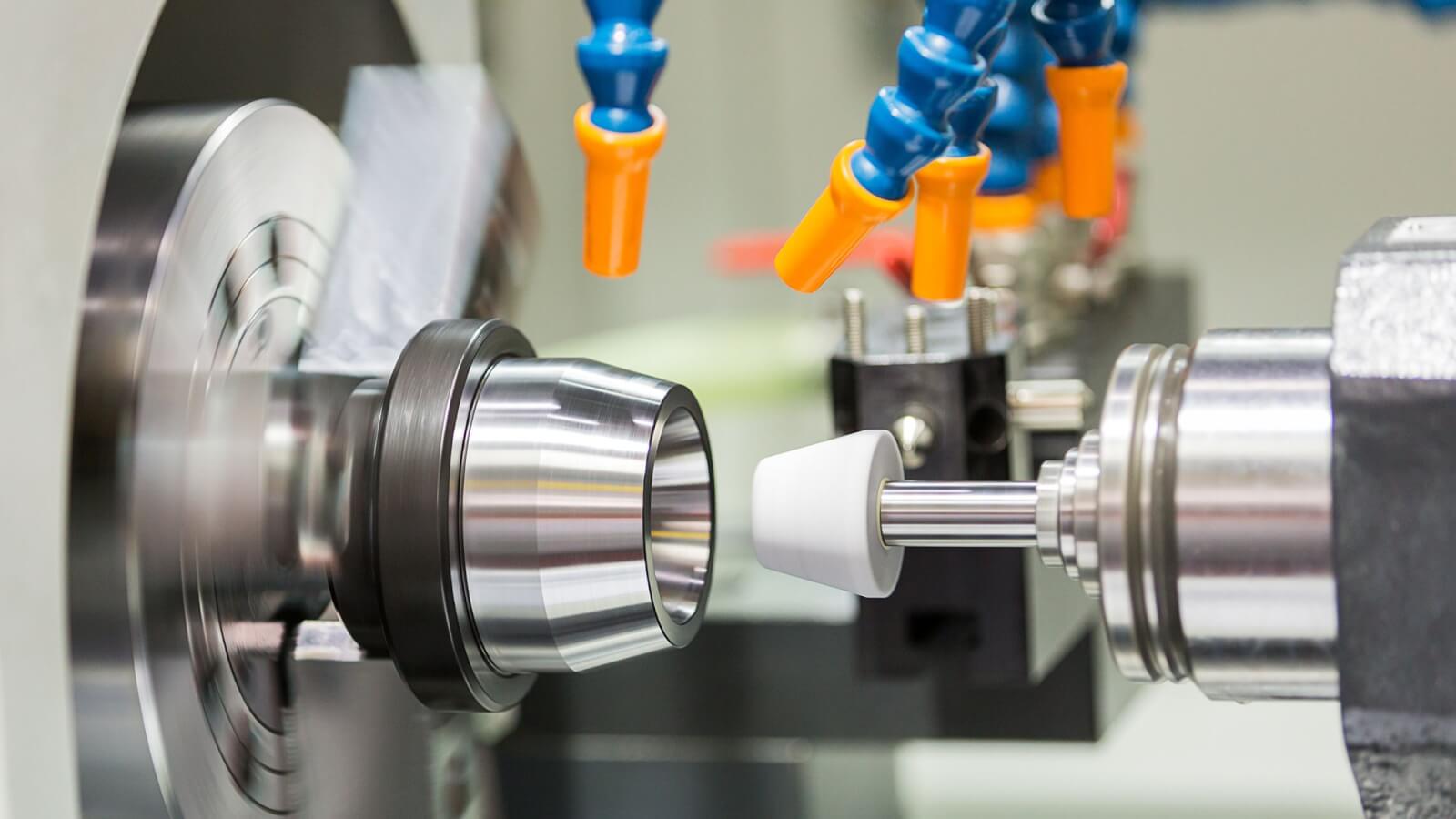

CNC Turning

Cylindrical Precision. Smooth Finishes. High-Speed Production.

CNC Turning is a subtractive process where the workpiece rotates while a stationary cutting tool shapes the part. Ideal for round, tubular, and symmetrical components, it delivers excellent dimensional accuracy and fine surface finishes.

- 1) Shafts, pins, bushings, spacers, fasteners, and threaded parts

- 2) Internal/external features: bores, grooves, threads, tapers

- 3) High-volume, fast-cycle production

- 4) Metals (Stainless Steel, Brass, Aluminum) and Plastics (POM, Nylon)

Note: With precision-controlled lathes and live tooling options, CNC turning offers tight tolerances, repeatability, and cost-effective performance — from prototype to production scale.

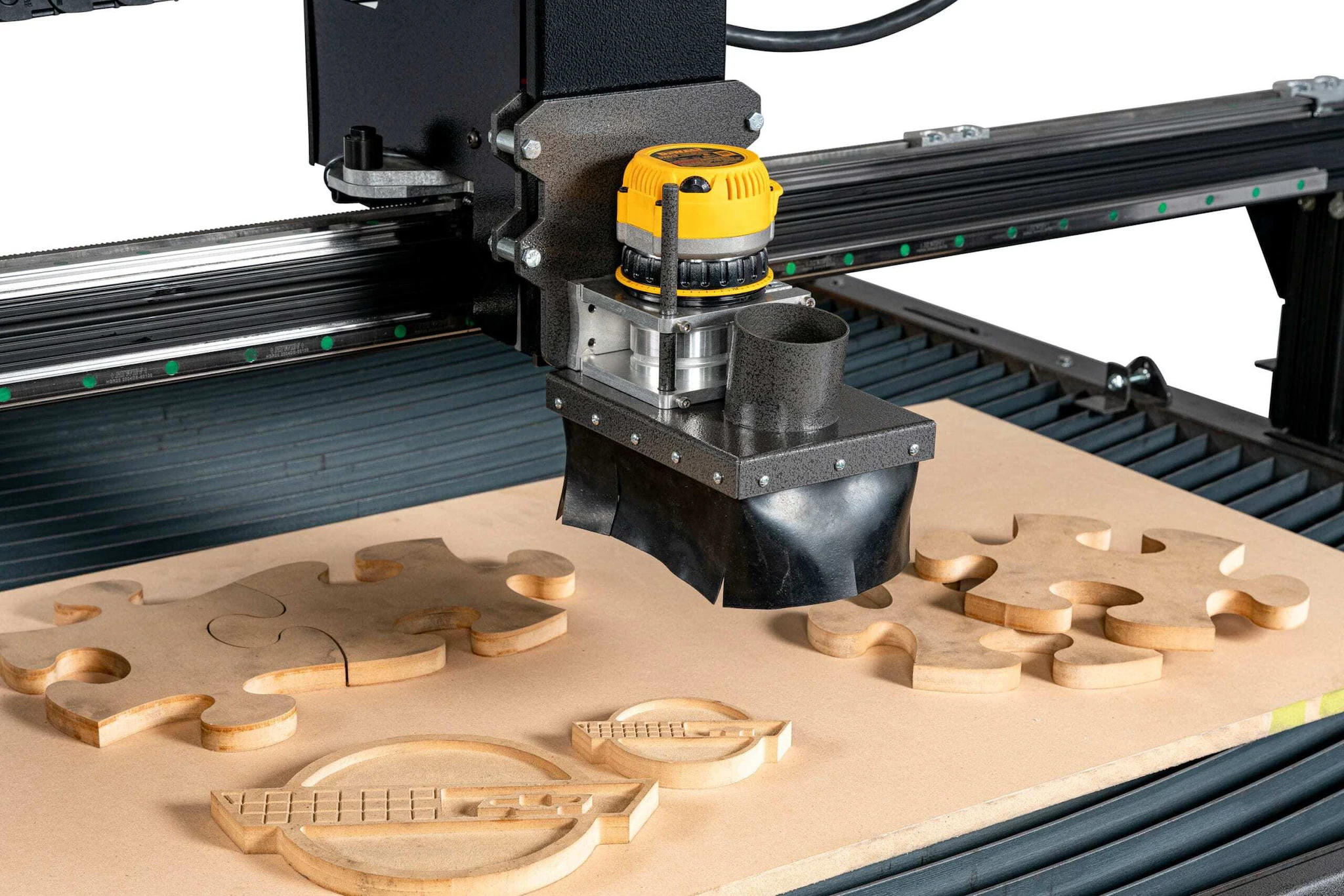

CNC Routing

High-Speed Machining for Large Sheets and Soft Materials

CNC Routing is ideal for cutting, engraving, and shaping large-format sheets of wood, plastics, composites, and soft metals. It uses high-speed rotating tools to deliver clean, precise cuts and complex profiles — especially for lightweight applications.

- 1) Panels, signage, fixtures, enclosures, and composite parts

- 2) Materials like MDF, acrylic, HDPE, polycarbonate, aluminum sheets

- 3) 2D and 2.5D contouring, pocketing, drilling, and engraving

- 4) Rapid production of flat or semi-flat parts with low tooling cost

Note: CNC routing offers high-speed material removal, smooth edge quality, and cost-effective production for large parts and sheet-based designs.

CNC Grinding

Ultra-Fine Surface Finishes & Tightest Tolerances

CNC Grinding uses an abrasive wheel to remove material with extreme precision. It’s best for finishing operations where surface flatness, roundness, and dimensional tolerances are critical — often to the micron level.

- 1) Hardened metals, precision tooling, and die components

- 2) Flat, cylindrical, or surface grinding

- 3) Achieving mirror finishes and ultra-tight tolerances (< ±0.005 mm)

- 4) Post-machining refinement and surface conditioning

Note: Ideal for aerospace, automotive, and tooling industries, CNC grinding ensures perfect geometry, minimal surface deviation, and high wear resistance.

Advanced CNC Machining

Multi-Axis, High-Complexity, Tight-Tolerance Parts

Advanced CNC Machining involves 4-axis, 5-axis, and live-tooling setups to produce highly intricate, multi-surface geometries in a single setup — reducing errors and machining time. It’s essential for complex prototypes, aerospace-grade parts, and high-precision production.

- 1) Complex surfaces, undercuts, compound angles

- 2) Aerospace, medical, motorsport, and high-end industrial components

- 3) Reduced fixture changes and improved part accuracy

- 4) Simultaneous machining across multiple axes

Note: With enhanced tool path control and integrated CAD/CAM workflows, advanced CNC delivers ultimate precision, speed, and design freedom — enabling next-gen innovation in every machined part.

Why choose Syntrof Tech

Choosing the Right Manufacturing Partner Matters Here’s Why Syntrof Tech Stands Out Every Time

When it comes to manufacturing and product development, you need a partner you can trust for speed, precision, and reliability. At Syntrof Tech, we combine cutting-edge technology with expert craftsmanship to deliver unmatched results. Whether you're creating prototypes, scaling production, or launching a new product, our team is committed to helping you succeed — every step of the way choose Syntrof tech and experience the difference that quality, experience, and innovation bring to your business.

Highest Quality

100+ Organized Manufacturing Vendors

Cutting-Edge Technology

Transparent Workflow Coordination

Fast Turnaround Time

Cost-Effective Solutions

Our Capabilities

Explore Our Complete Range of Manufacturing and Product Development Capabilities

At Syntrof Tech, we offer a wide range of manufacturing and product development services to meet the growing demands of businesses across the globe. From rapid prototyping to large-scale production, our solutions are designed for speed, precision, and cost-efficiency. Explore our core services below and find the perfect solution for your next project.

Additive Manufacturing

Rapid prototyping and production-grade 3D printing using high-performance materials. Perfect for quick product development and testing.

CNC Machining

High-precision CNC milling, turning, and drilling services for metal and plastic parts with tight tolerances and fast delivery.

Sheet Metal Fabrication

Custom sheet metal components for automotive, construction, and industrial use. High strength, clean finishes, and flexible designs.

Casting & Forging

Precision forging and casting solutions for OEMs and industrial manufacturing applications.

Injection Molding

From prototype molds to full-scale production runs. Efficient molding processes for plastic parts with consistent quality.

New Product Development

Complete design to manufacturing services. Transform your idea into a market-ready product with expert support at every stage.

For all the reasons which brought you here

Let's Connect!

Follow Us on

Stay connected with our Insights, innovations, and updates

frequently asks questions

Real Stories From Satisfied Customers Who Trust Our Manufacturing Expertise in India

At Syntroftech, client satisfaction is not just a goal – it’s our commitment. Here’s what business owners, engineers, and product developers from across India have to say about partnering with us. From startups to large enterprises, their words inspire us to push boundaries every day!

What industries does Syntrof Tech serve?

We serve Automotive, Industrial, Electronics, Construction, Education, Electric Vehicles, Agriculture, Solar, Architecture, and Healthcare sectors across India.

Can you handle bulk manufacturing orders?

Yes, we specialize in both small batch and bulk production with high quality standards.

How fast can you deliver 3D printed prototypes?

Depending on the design complexity, we usually deliver prototypes within 3 to 7 working days.

Which materials are available for CNC machining?

We offer metals like aluminum, steel, copper, and plastics like ABS, POM, and others.

Is product design assistance available?

Yes, our design team can assist you from concept development to prototyping.

Can you create custom sheet metal parts for industrial machinery?

Absolutely! We specialize in custom sheet metal fabrication for various industries.

What is the typical lead time for injection molding projects?

Injection molding projects usually take 2 to 6 weeks depending on tooling and order size.

How do you ensure the quality of manufactured parts?

We follow strict quality control protocols, including material testing and final inspection before dispatch.